BC8220

Next generation PCBN grade for hardened steel turning

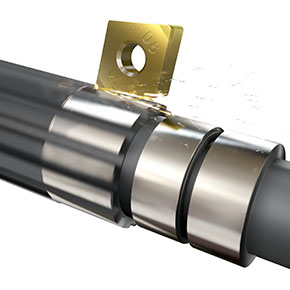

For the effective light to medium continuous and interrupted turning of high hardened steels, Mitsubishi Materials has developed a new and innovative coated PCBN insert grade, BC8220. This new tool has extended the comprehensive range of turning inserts that are available. The grade incorporates state of the art, multi layer PVD coating technology that provides outstanding wear resistance.

High specifications to provide cost effectiveness

- Longer tool life and reliability provided by the special multi layer coating

- Less inventory – Versatile range of applications can be machined meaning a reduction of tooling costs

- Cost effective multi edge inserts

- Time saving, easy identification of used edges enabled by the gold coloured top coating layer

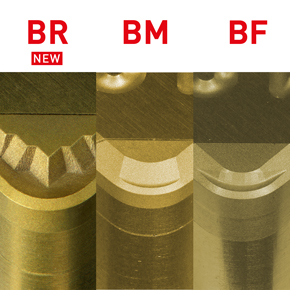

- Three chipbreakers BR / BM / BF for better chip control in hard-soft machining of components with carburised layers and high cutting depths.

- New BR chipbreaker for good chip control in high cutting depths up to 1 mm.

Technology creates usability

- Super multi layer PVD coating technology gives outstanding wear and chipping resistance

- Increased binding strength to the substrate enables a toughening effect against peeling

- Optimised substrate technology - An ultra micro grain particle binder connects the CBN particles that allows cutting forces to be dispersed evenly and helps to prevent cracking and fracturing.

- Precision edge honing preparations, including the new VA type for versatility.

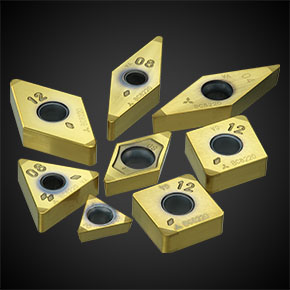

Wide choice of inserts

- 8 negative geometry types – CNGA, CNGM, DNGA, DNGM, SNGA, TNGA, VNGA and WNGA.

- 8 positive geometry types - CCGT, CCGW, DCGT, DCGW, TPGB, CPGB, VBGW and VCGW.

- 5 edge honing types – GA, GH, TA and TH plus the new multi-purpose VA type.

Newsletter

© 2025 – Mitsubishi Materials Tools Europe GmbH