DXAS DRILLS

Exchangeable head carbide drills with a revolutionary head replacement system. It dramatically reduces running costs and achieves machining accuracy and efficiency comparable to solid drills.

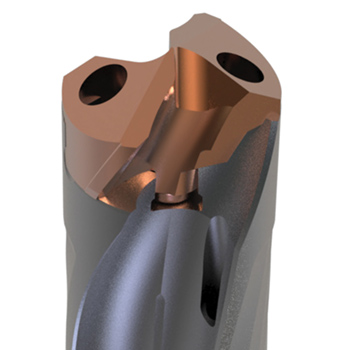

The ultimate combination of clamping strength and accuracy for ease of use

- The two-screw fastening suppresses deformation of the holder and enables high-strength fastening, that provides process security even in high-stress machining environments.

- Reduces tool change time by improving accuracy and a providing a longer tool life.

- Perfect centering minimises the misalignment of the central axes of the head and holder that occurs when fastened.

Technology creates usability

The two-screw fastening suppresses deformation of the holder and enables high-strength fastening, so it is less likely to loosen and securely fixes the head. The central location spigot also provides perfect centering.

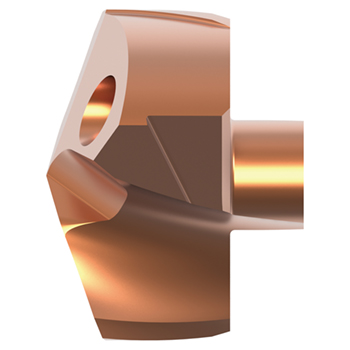

XR Point Thinning - Through Coolant holes – Advanced Flute Geometry

By smoothly curling the chips, low resistance and excellent chip separation are achieved. The low resistance design achieves highly efficient machining and reduces power consumption during machining. The new positioning of coolant holes supplies coolant directly onto the cutting edge. In combination with the flute geometry provides excellent chip disposal.

Sizes and Insert Grade

DXAS from Ø18 – Ø30 in cutting lengths L/D 1.5, 3, 5 and 8

Exchangeable insert grade DP6020 for steels and cast iron.