MH515 & BC5110

Uproszczenie w kłopotliwych aplikacjach

Prezentujemy dwa nowe gatunki do trudnych aplikacji toczenia żeliwa i staliwa nierdzewnego.

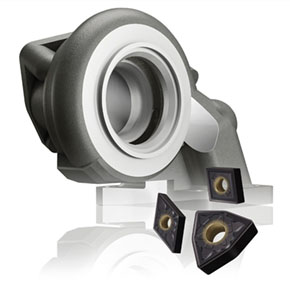

MH515 to gatunek pokrywanego węglika do zastosowań specjalnych - przeznaczony do obróbki odlewów ze staliw austenitycznych oraz żeliw sferoidalnych stosowanych zwykle w korpusach turbosprężarek.

BC5110 jest gatunkiem CBN pokrywanym metodą PVD, przeznaczonym szczególnie do obróbki szarych żeliw, np. GG25 i GG30. Są to materiały regularnie wykorzystywane do produkcji części samochodowych.

Cechy dostosowane do specjalnych aplikacji

- MH515

- Niezawodność i dłuższa żywotność narzędzia dzięki specjalnej, wielowarstwowej powłoce

- Zwiększona liczba detali na krawędź i niższe koszty obróbki staliwa nierdzewnego BC5110

- Zredukowany koszt na krawędź efektem zastosowania drobnoziarnistej struktury i zaawansowanej technicznie powłoce

- Mniejsze koszty magazynowania – jeden gatunek do wielu aplikacji z możliwością wyboru rodzaju zaszlifowania krawędzi

Wysoka użyteczność dzięki nowoczesnej technologii

- MH515

- Technologia pokrywania nanostrukturą Al2O3 warstwy bazowej TiCN zapewnia wyjątkową odporność na zużycie

- Wykorzystanie technologii Tough grip powoduje lepsze przyleganie do siebie warstw powłoki co zapobiega powstawaniu odprysków BC5110

- Drobnoziarniste podłoże i wysoka zawartość CBN skutkują większą stabilnością obróbki w porównaniu do produktów konwencjonalnych

- Precyzyjne zaszlifowanie krawędzi typu FS i GS dostarcza idealne rozwiązania do trudnych aplikacji

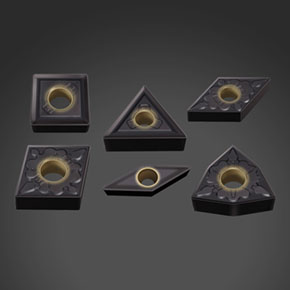

Szeroki wybór płytek

- MH515

- Typy w geometrii negatywnej – CNMG, CNMA, DNMG, SNMG, TNMG, VNMG, WNMG

- Typy w geometrii pozytywnej - VCMT, VCMW BC5110

- Typy w geometrii negatywnej – CNGA, DNGA, SNGA, TNGA, VNGA

- Typy w geometrii pozytywnej - VBGW, CCGW, DCGW, TCGW, TPGB, SPGN

Zarejestrować

© 2025 – Mitsubishi Materials Tools Europe GmbH