MC6100

MC6100 series expansion

To complement the existing negative geometry inserts, there s now a new range of 5°, 7° and 11° positive inserts for the MC6100 series.

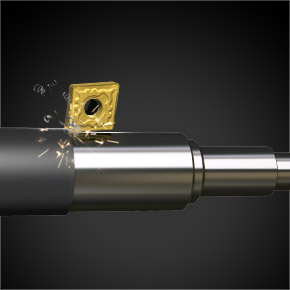

MC6115 is a special purpose carbide grade with state-of-the-art CVD coating for super efficient, high speed machining of steels.

MC6125 is a versatile grade and the first recommendation for a wide range of applications.

Ultimate performance combined with outstanding tool life

- Latest coating technology provides dramatic improvements in heat and wear resistance for longer tool life thereby reducing overall tooling costs.

- Protection against sudden fracturing during interrupted cutting reduces scrap rates.

- Reduces tool change time by enabling better consistency of dimensional accuracy and surface finishes.

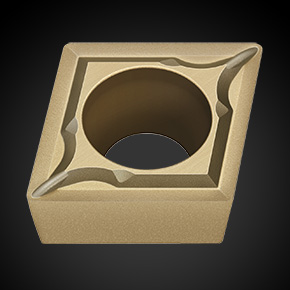

- Gold colour of top coating enables easy identification of edges already used.

Technology creates usability

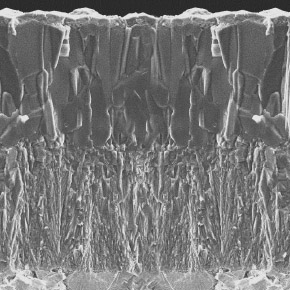

- Super Nano Texture coating technology - Al2O3 with a TiCN base layer gives outstanding wear resistance.

- Special developments in the coating process has reduced the residual tensile stress found within conventional coating structures. This means that cracks formed during the impact of machining are dissipated much more effectively and thereby help prevent sudden fracturing and also brings greater process reliability.

- Tough grip technology enables greater adhesion between layers for a toughening effect against peeling.

Wide choice of negative geometry and NEW positive geometry inserts and chipbreakers

Positive types available 5º, 7º and 11º

- Chipbreakers

- For finish cutting– FP, FV and SVX SH, SA and SW

- For light cutting – LP and SW

- For medium cutting – MP, MV, MW and standard

- For heavier cutting RR and Flat top for cast iron

- Negative geometry inserts

- 6 types – CNMG, DNMG, SNMG, TNMG, VNMG, WNMG

- 11 chipbreaker types

Inscription à notre lettre d’information

© 2025 – Mitsubishi Materials Tools Europe GmbH