MC6125

New technology provides choice and reliability

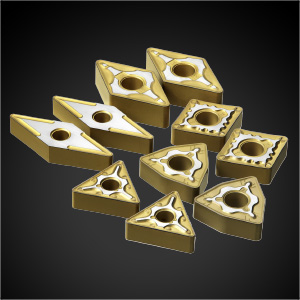

Introducing the new MC6125 grade, a comprehensive range of inserts that becomes the first choice for the high-performance and reliability when turning a wide range of carbon and alloy steels.

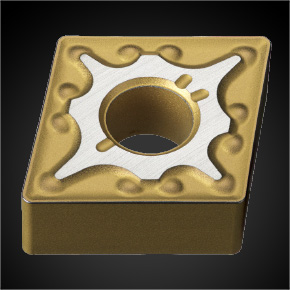

MC6125 is a general purpose carbide grade with state-of-the-art CVD coating for super efficient machining of steels.

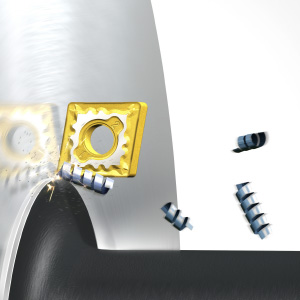

Ultimate performance combined with outstanding tool life

- The new coating technology provides dramatic improvements in heat and wear resistance for longer tool life thereby reducing overall tooling costs.

- Protection against sudden fracturing during interrupted cutting reduces scrap rates.

- Reduces tool change time by enabling better consistency of dimensional accuracy and surface finishes.

- Gold colour of top coating enables easy identification of edges already used.

Technology creates usability

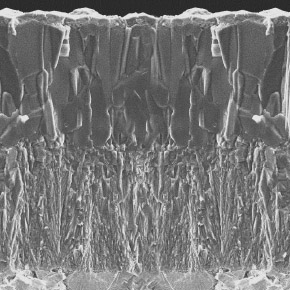

- Super Nano Texture coating technology - Al2O3 with a TiCN base layer gives outstanding wear resistance.

- MC6125 uses a new surface treatment at cutting edge for increased stability. Additionally the single layers are made with special smooth preparation that provides improved adhesion to enable a wider range of applications.

- Tough grip technology enables greater adhesion between layers for a toughening effect against peeling.

Wide choice of inserts and chipbreakers

- MC6115

- 6 negative geometry types – CNMG, DNMG, SNMG, TNMG, VNMG, WNMG

- 11 chipbreaker types

For light cutting – LP, SH, SA and SW

For medium cutting – MP, MA, MH, Standard, and MW

For rough cutting – RP and GH

Newsletter

© 2025 – Mitsubishi Materials Tools Europe GmbH