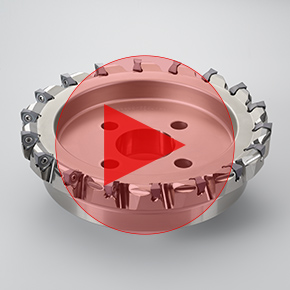

WWX400

Technology Brings Performance and Machining Profitability

The WWX400 series from Mitsubishi Materials combines the latest cutter geometry and carbide insert technology. Bringing versatility and performance to ensure machining efficiency, component accuracy and process reliability. All of which are essential in todays market to bring cost benefits from reduced down times, faster machining cycles and reduced inventories.

Versatile and Cost Effective

- 6 cutting edges per insert

- Multi functional – reduces overall set up process and in-cycle tool changes

- Accurate wall machining cuts finishing times

- Secure clamping lessens vibration for longer tool and machine life

- Choice of grades and chipbreakers allows versatility and shrinks inventory costs

High tech, unique design

- X geometry provides an innovative insert pocket, enabling accurate, secure and repeatable clamping

- Thicker inserts with positive leading edge geometry means lower cutting forces

- Minor cutting edge with wiper type features gives smooth machined surface finishes

- Cutter bodies with through coolant ports to each insert

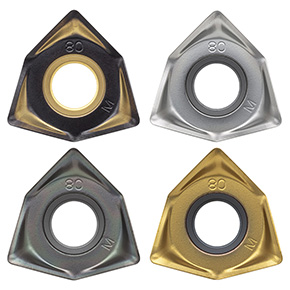

- Mitsubishi’s state-of-the-art PVD, CVD and uncoated micro-grain carbide insert grades

Choice means flexibility

- 8 insert grades provides multi material machining possibilities

- Further usability enhanced with 3 different chipbreakers for light through to rough machining

- Arbor type: DC Ø 50 – 250 mm

- Shank type: DC Ø 50 – 80 mm

- Inserts with radii: 0.4 – 0.8

Depth of cut: APMX 8 mm

Newsletter

© 2025 – Mitsubishi Materials Tools Europe GmbH