DVAS

Risolvere i problemi della foratura profonda di piccolo diametro

La foratura convenzionale di fori profondi, soprattutto quando si producono fori di piccolo diametro, è solitamente un processo lento e inaffidabile. Le mini punte DVAS sono state progettate fin dall'inizio specificamente per eseguire fori di piccolo diametro. Sono ideali per un'ampia gamma di materiali che vanno dagli acciai legati ed inossidabili, alla ghisa, all’alluminio fino al cromo cobalto, HRSA e leghe di titanio. La serie DVAS è un pacchetto completo di soluzioni per la mini-foratura profonda. Con una vasta gamma di lunghezze ed un set dedicato di punte pilota che garantisce la completa compatibilità durante l'intero processo di foratura.

Affidabilità ed efficienza

- Aumento della produttività garantita dai fori di lubrorefrigerazione di forma trilobata.

- Super affidabilità grazie all'assottigliamento del nocciolo XR che rompe i trucioli riducendo le forze di taglio.

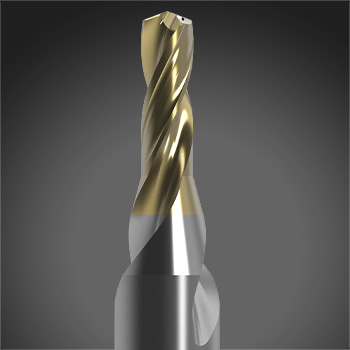

- Esclusiva forma dell’elica sulla parte conica della rastremazione che aumenta la rigidità complessiva per una migliore precisione del foro.

- Speciale qualità DP1120 con rivestimento PVD multistrato che garantisce una lunga durata dell'utensile e riduce i costi complessivi.

5 tecnologie portano un nuovo standard di settore

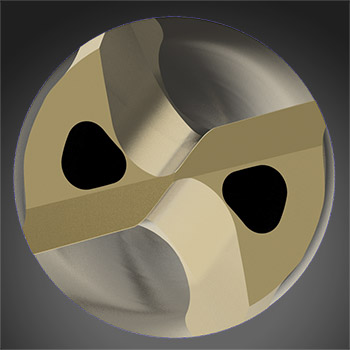

- Fori a forma trilobata per un maggiore flusso di lubrorefrigerante

- Taglienti diritti, affilati ma resistenti

- Assottigliamento del nocciolo XR che rompe i trucioli garantendo un flusso ottimale

- Elica che termina nella rastremazione conica che garantisce una maggiore rigidità

- Grado DP1120 con rivestimento PVD tenace e resistente all'usura

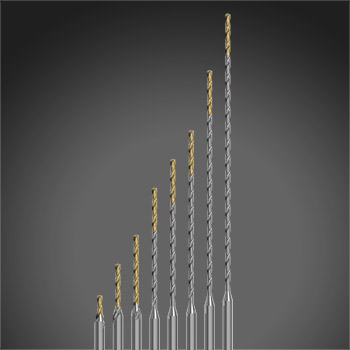

Ampia scelta di diametri

- DVAS

- Diametri da Ø1mm. a 2.9 mm

- Incrementi di 0.1 mm

- Punte pilota DVAS L/D = 2

- Punte standard DVAS L/D = 2 fino a L/D = 50

Newsletter

© 2025 – Mitsubishi Materials Tools Europe GmbH