DLE

Simplicity of design brings multi-functionality

The new DLE series of centre drills from Mitsubishi Materials are more than first meets the eye. By combining the best of materials, coatings and smart design means the simple centre drill has morphed into a much more useful tool. With the modern necessity to reduce inventory costs even further, the DLE drill delivers multi-functional features without compromising accuracy.

Capable, durable and fast

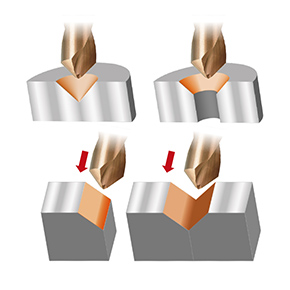

- Multi functional – reduces overall set up process and in-cycle tool changes

- Precise centre spotting and repeatability for super accurate hole drilling

- Edge and point sharpness contributes to burr free centre drilling

- One grade suitable for drilling a wide range of materials for lower inventory costs

Technology creates usability

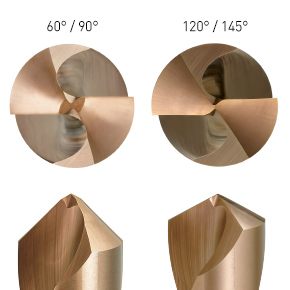

- Thinned point geometry (60° and 90° types) enables a low cutting force and smooth chip discharge

- Double point angle at 60° and 90° types provides high positioning accuracy

- Sharp cutting edges combined with high fracture resistance enables multi-functionality

- Long life combines accurate and burr free spot drilling for precision hole drilling

- State-of-the-art PVD coating – DP1020 (accumulated AlTiCrN) raises tool hardness to over 2900 Hv to give high wear resistance and long tool life

- Excellent surface roughness and no burrs

- Ideal for drilling mild, carbon and alloy steels, stainless steel and cast iron materials

Straightforward choice

- 4 drill point angles 60, 90, 120 and 145 deg. available

- Standard shank sizes suitable for collets

- 60° type – Ø3 – 12 mm

- 90° type – Ø3 – 16 mm

- 120° type – Ø3 – 12 mm

- 145° type – Ø3 – 12 mm

Newsletter

© 2025 – Mitsubishi Materials Tools Europe GmbH