Alimaster

Gamma completa di frese ad alte prestazioni per la lavorazione di leghe di alluminio

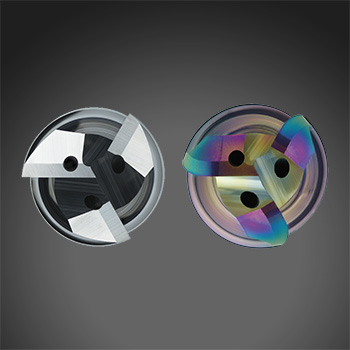

La consolidata serie Alimaster di Mitsubishi è ora ancora più efficiente grazie all'aggiunta di 2 nuove tipologie, una con geometria a spigolo a 3 eliche ed una torica sempre a 3 eliche. Sono inoltre disponibili con un nuovo rivestimento DLC ad alta tecnologia. Tutti i vantaggi dell'affidabile serie standard Alimaster, che può essere utilizzata per lavorare in modo efficiente le leghe di alluminio, sono presenti anche nelle nuove tipologie.

Serie completa per tutte le applicazioni su alluminio

- Nuove tipologie con rivestimento DLC per una durata eccezionale

- Prestazioni ed affidabilità migliorate con la tecnologia di affilatura 5 assi in continuo

- Capacità di avanzamento assiale incrementata grazie ad una nuova geometria del tagliente centrale

- Migliore smaltimento dei trucioli grazie alla lubrorefrigerazione interna alle eliche ed alla lucidatura delle stesse.

- Sovrapposizione delle passate uniforme durante la lavorazione di pareti profonde con geometria finale dell’elica raggiata

Innovazioni

- L’esclusivo rivestimento DLC offre la massima resistenza all’incollamento dei trucioli durante la lavorazione ad alta velocità

- I fori di lubrorefrigerazione ricavati nell’elica garantiscono un eccellente flusso di refrigerante

- Le eliche variabili permettono un’ottima prevenzione delle vibrazioni

- Le eliche lucidate al fine di garantire un efficiente smaltimento dei trucioli prevengono l'intasamento

- Geometria del tagliente centrale ottimizzata per una maggiore resistenza durante la lavorazione a tuffo

- Rettifica eseguita con processo a 5 assi in continuo per precisione ed affidabilità

Grande gamma di diverse tipologie di Alimaster + nuove tipologie a 3 taglienti a spigolo e toriche

- 3 taglienti a spigolo, tipologie nude e rivestite DLC

DLC3SA e A3SA Ø12, 16, 20 e 25mm - Toriche 3 taglienti, tipologie nude e rivestite DLC

DLC3SARB e A3SARB Ø12, 16, 20 e 25mm con raggi torici da 1 mm a 5 mm

Newsletter

© 2025 – Mitsubishi Materials Tools Europe GmbH